The lathe, a versatile and indispensable tool in the world of woodworking and metalworking, has been used since ancient times to shape and manipulate a variety of materials with precision. Whether you are a seasoned craftsman or a budding enthusiast, mastering the art of using a lathe can open up a world of possibilities for creating intricate designs and functional objects. In this article, we will provide you with a comprehensive guide on how to use a lathe, covering everything from selecting the right lathe for your needs to mastering basic techniques and safety precautions. So, grab your turning tools and let’s embark on a journey to unleash your creativity and craftsmanship.

Introduction

Using a lathe can seem intimidating at first, but with a little practice and guidance, you’ll soon be able to create beautiful and precise woodturning projects. In this post, we’ll walk you through the basics of how to use a lathe, including safety precautions, essential tools, and step-by-step instructions for getting started.

Before you dive into woodturning, it’s essential to familiarize yourself with the safety precautions. Always wear protective gear such as safety goggles, a dust mask, and ear protection. Additionally, make sure the lathe is securely mounted to a workbench or sturdy surface. Keep the work area clean and free of clutter to avoid accidents and ensure optimum performance of the lathe.

Next, gather the necessary tools for your woodturning projects. You’ll need a variety of lathe chisels, such as spindle gouges, parting tools, and skew chisels. It’s important to select the appropriate chisel for different woodturning techniques and finishes. Additionally, you’ll need a faceplate or chuck to securely hold your workpiece, as well as a tailstock with a live center for added support.

To begin using the lathe, start by adjusting the tool rest to the desired height and position. This will provide support for your chisels while reducing the risk of injury. Adjust the speed of the lathe according to the size and type of wood you’re working with. A slower speed is suitable for larger, unbalanced pieces, while faster speeds are ideal for smaller and more balanced work.

Once your lathe is set up and your tools are ready, it’s time to start turning! Begin by mounting your workpiece securely onto the lathe’s faceplate or chuck. Ensure the piece is symmetrical and properly balanced to avoid vibrations. Start with gentle cuts and gradually increase pressure as you become more comfortable. Use firm, controlled movements to shape and refine the wood, and always follow the natural grain direction.

As you gain experience with the lathe, you can explore a wide range of woodturning techniques, such as creating intricate designs, hollowing out vessels, and even carving threads. Don’t be afraid to experiment and let your creativity shine. Remember to take breaks and regularly inspect your tools and lathe for any signs of wear or damage. With time and practice, using a lathe will become second nature, allowing you to embark on rewarding and satisfying woodturning projects.

Safety Precautions

The use of a lathe machine requires strict adherence to to ensure the well-being of the operator. By following these guidelines, you can minimize the risk of accidents and create a safe working environment:

1. Personal Protective Equipment (PPE)

- Always wear safety goggles or a face shield to protect your eyes from flying debris.

- Wear a dust mask or respirator to prevent inhalation of harmful substances such as wood or metal dust.

- Use earplugs or earmuffs to protect your hearing from the noise generated by the lathe machine.

- Wear snug-fitting clothing and avoid loose accessories that could get caught in the machine.

2. Machine Inspection

Prior to using the lathe, it is crucial to inspect the machine for any signs of damage or wear. Look for loose components, frayed cables, or malfunctioning parts. Ensure all guards and safety features are in place and functioning properly.

3. Work Area Safety

- Clear the work area of any clutter, debris, or flammable materials that could pose a hazard.

- Ensure there is adequate lighting to clearly see your workpiece and the machine’s controls.

- Position the lathe in a stable manner, either bolted to a workbench or secured on a level surface.

- Keep bystanders at a safe distance from the machine while it is in operation.

4. Tool Handling and Operation

Correct handling of lathe tools is essential for your safety:

- Always maintain a firm grip on the tool, keeping your hands and fingers away from the cutting area.

- Ensure the tool rest is properly adjusted and securely tightened to provide a stable support for the workpiece.

- Avoid overloading the machine by removing excess material gradually with each pass.

- Never leave the lathe unattended while it is in operation.

5. Emergency Preparedness

Despite taking precautions, accidents may still occur. Be prepared for emergencies:

| Situation | Action |

|---|---|

| Fire outbreak | Keep a fire extinguisher within reach and know how to use it. |

| Personal injury | Have a first aid kit available and know basic first aid techniques. |

| Machine malfunction | Know the location of the emergency shut-off switch and how to use it. |

Remember, safety should always be your utmost priority when using a lathe machine. By following these precautions and utilizing adequate personal protective equipment, you can minimize the risks associated with lathe work and ensure a safe and enjoyable experience.

Choosing the Right Lathe and Tools

When it comes to for your projects, there are a few key factors to consider. From the size and weight of the lathe to the type of tools you need, each decision will impact the quality of your work. Here we will discuss some important considerations to help you make an informed decision and ensure that you are using your lathe effectively.

Size and Weight

One of the first things to consider when choosing a lathe is its size and weight. This will depend on the size of the projects you plan to work on and the available space in your workshop. If you have limited space, a smaller, more portable lathe may be a better choice. On the other hand, a larger lathe will allow you to work on larger pieces but will require more dedicated space.

Type of Lathe

There are various types of lathes available, such as benchtop lathes, engine lathes, and woodturning lathes. Each type has its own advantages and best applications. If you primarily work on small projects or hobbyist items, a benchtop lathe may be sufficient. However, if you need to handle larger or more complex projects, an engine lathe or woodturning lathe might be more appropriate.

Tools and Accessories

Choosing the right tools and accessories is essential for achieving the desired results with your lathe. Start with the basics, such as a roughing gouge, spindle gouge, parting tool, and skew chisel. These tools will cover a wide range of turning operations. Additionally, consider investing in a quality chuck to securely hold your workpieces, and various jigs and guides to assist in specific tasks. Don’t forget to have a good selection of safety equipment, like face shields and dust masks, to protect yourself during operation.

Material Compatibility

Another crucial factor when using a lathe is the compatibility of the lathe and tools with the materials you plan to work on. Different lathes and tools are better suited for specific materials. For example, woodturning lathes have features that make them ideal for woodturning projects, while metal lathes are designed to handle metalworking tasks. Consider the type of materials you will be working with and ensure that your lathe and tools can handle them effectively and safely.

Budget and Quality

Lastly, consider your budget and the quality of the lathe and tools you are considering. Investing in a high-quality lathe and tools will ensure longevity and better performance. While it may be tempting to opt for cheaper options, they may not offer the same level of accuracy and durability. Evaluate your budget and strike a balance between cost and quality to ensure you make a wise investment that will serve you well in the long run.

Basic Techniques for Operating a Lathe

When it comes to using a lathe, mastering the basic techniques is crucial for achieving precision and efficiency in your turning projects. Whether you are a beginner or looking to refine your skills, this post will guide you through the fundamental techniques that every lathe operator should know.

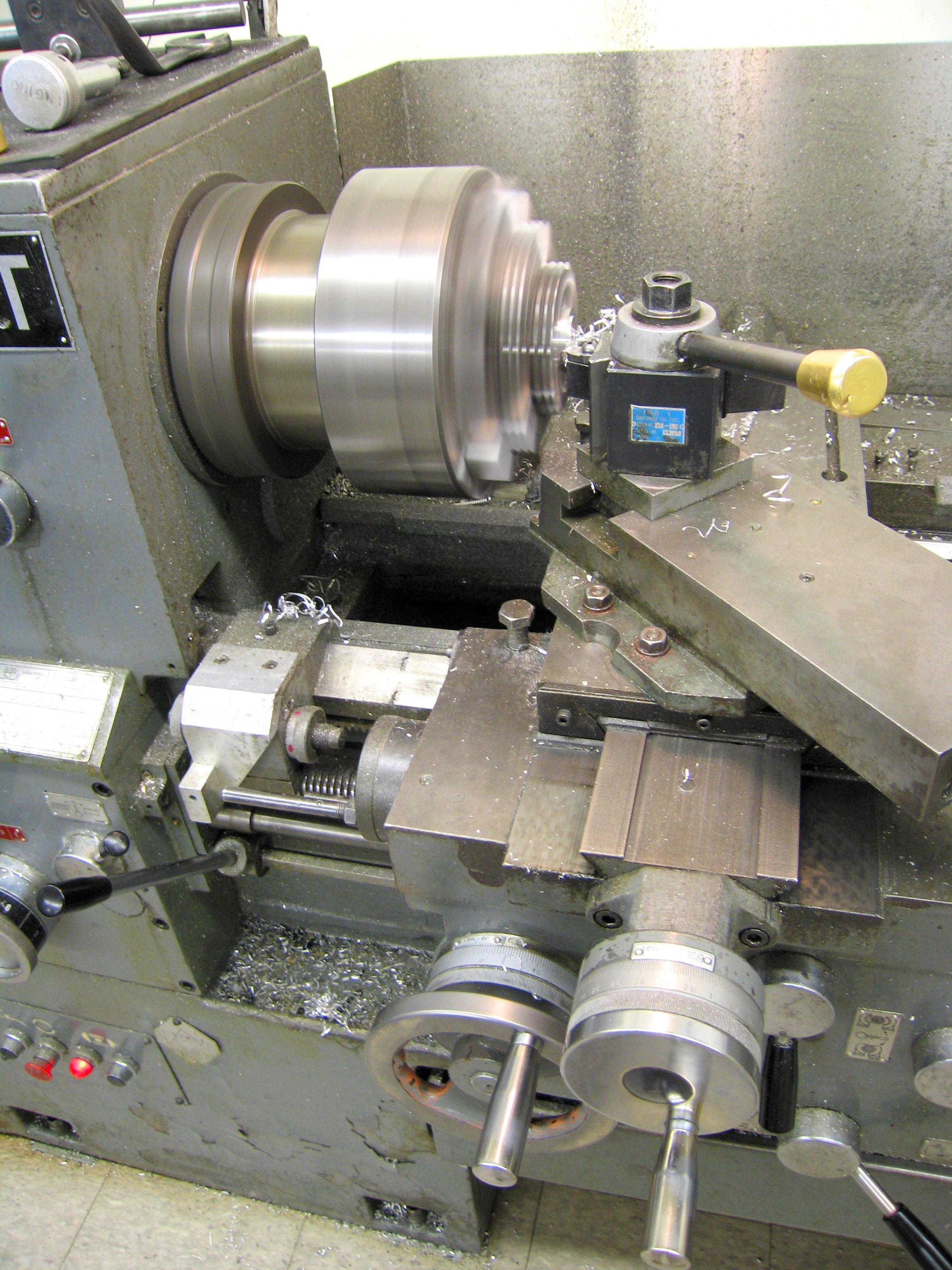

Familiarize Yourself with the Lathe Parts

Before jumping into using a lathe, take some time to acquaint yourself with its various components. Understanding the different parts of the lathe, such as the spindle, tailstock, tool rest, and chuck, will help you work more effectively. Refer to the manual provided by the manufacturer for detailed information on your specific lathe model.

Securing the Workpiece

Properly securing the workpiece is essential for safety and accurate turning. Begin by ensuring the lathe is switched off, install a faceplate or chuck on the spindle, and fasten it securely. Next, carefully mount your workpiece onto the faceplate or directly onto the chuck, making sure it is tightened firmly. This will prevent any movement or slippage while you work.

Selecting and Sharpening Lathe Tools

The choice of lathe tools greatly influences the quality of your turning work. Select the appropriate tools for the specific cutting task and ensure they are sharp before beginning. Dull tools can lead to rough finishes, inaccurate cuts, and increase the risk of accidents. Regularly sharpen your tools using a bench grinder or a sharpening system to maintain their cutting edge.

Mastering Basic Cutting Techniques

Understanding cutting techniques is crucial for successful lathe operations. Start by positioning the tool rest at the appropriate height and as close to the workpiece as possible without risking collisions. Take small cuts initially, gradually increasing the depth as you gain confidence. Use light pressure and avoid forcing the tool, letting it cut at its own pace. Additionally, keeping your tools sharp and properly aligned will enhance your cutting results.

Maintaining a Safe Working Environment

Prioritize safety while operating a lathe to prevent accidents and injuries. Always wear appropriate personal protective equipment, such as safety glasses or a face shield, to protect your eyes from flying debris. Ensure the lathe is properly grounded and stable. Keep the surrounding area clean and free from clutter. Regularly inspect the lathe for any loose parts, worn-out belts, or damaged components.

| Tool | Recommended Task |

|---|---|

| Bowl Gouge | Hollowing out bowls or vases |

| Skew Chisel | Producing smooth and precise cuts |

| Parting Tool | Creating grooves, parting off workpieces |

Remember, mastering the lays the foundation for more advanced turning projects. With practice and patience, you will gain confidence in your abilities and be able to produce stunning turned pieces. By following these guidelines, you can enjoy a safe and rewarding experience while using a lathe.

Advanced Tips and Best Practices

Here are some to help you get the most out of using a lathe:

1. Safety First: Before using a lathe, always ensure that you are wearing the appropriate safety gear, including safety glasses, a face shield, and ear protection. Make sure the lathe is properly secured to avoid any vibration or movement during operation. Keep your hands away from rotating parts and use push sticks or other tools to operate the lathe whenever possible.

2. Choosing the Right Tools: To achieve precise and smooth cuts, it’s essential to use the right tools for the job. Make sure your lathe tools are sharp and properly sharpened. Different shapes and sizes of lathe tools are available for specific tasks, so choose the appropriate tool to achieve the desired results. Remember to always position the tool rest as close as possible to the piece you’re working on for added stability.

3. Selecting the Right Speed: The speed at which the lathe rotates can greatly affect the quality of your work. Generally, larger pieces require slower speeds, while smaller pieces can be turned at higher speeds. Experiment with different speeds to find the optimal setting for the material you’re working on. Keep in mind that roughing cuts typically require a slower speed, while finishing cuts can be done at higher speeds for a smoother result.

4. Checking for Balance: Before starting a turning operation, always check for balance. Irregular weight distribution on the lathe can cause vibrations and affect the quality of your work. If you notice any wobbling or vibrations, adjust the workpiece or use counterweights to achieve better balance. Taking the time to ensure balance will result in smoother cuts and a better finished product.

5. Properly Finishing the Piece: Once you have completed the turning process, it’s important to properly finish the piece for a polished look. Use sandpaper to smooth any rough surfaces, starting with a coarser grit and gradually working your way to a finer grit for a smooth finish. Additionally, applying a proper finishing product such as wax or lacquer can enhance the appearance and durability of your work.

| Tool Shape | Recommended Use |

|---|---|

| Bowl Gouge | Used for creating concave shapes on the inside of bowls or hollow forms. |

| Skew Chisel | Ideal for producing smooth and flat surfaces, as well as creating straight or straight-edged cuts. |

| Parting Tool | Designed for creating deep cuts, separating workpieces, and making accurate diameters or grooves. |

| Spindle Gouge | Primarily used for turning spindles or any cylindrical work with intricate detail. |

| Scraper | Best for smoothing or removing imperfections on flat or convex surfaces. |

Q&A

Q: What is a lathe and how does it work?

A: A lathe is a machine tool used in woodworking or metalworking. It operates by rotating a workpiece against a cutting tool to shape and size it according to the desired specifications.

Q: What are the common types of lathes?

A: The most common types of lathes are engine lathes, bench lathes, and turret lathes. Each type is designed for specific applications and has its own unique features and capabilities.

Q: How do I choose the right lathe for my needs?

A: When choosing a lathe, factors like the size and type of workpieces you plan to handle, your level of experience, and your budget should be taken into account. Researching and seeking advice from experts can help you make an informed decision.

Q: What safety precautions should I take before using a lathe?

A: Prior to using a lathe, always wear appropriate personal protective equipment such as safety glasses, gloves, and hearing protection. Make sure the lathe is properly maintained, well-lubricated, and that all guards and safety devices are in place. Additionally, familiarize yourself with emergency shutdown procedures.

Q: What are the basic steps for setting up a lathe?

A: To set up a lathe, begin by installing the necessary cutting tools, ensuring they are properly aligned and securely tightened. Adjust the tailstock and tool rest for optimal positioning. Also, ensure the workpiece is securely mounted and balanced if possible.

Q: How can I properly align the cutting tools on a lathe?

A: To align the cutting tools, use an alignment gauge or dial test indicator to ensure they are parallel to the lathe’s bed. Any misalignment can lead to poor quality cuts or even damage to the lathe.

Q: Can you explain the process of turning a workpiece on a lathe?

A: The process of turning involves moving the cutting tool against the rotating workpiece to shape it. This may include cutting various profiles, turning the workpiece to a specific diameter, or creating threads. Applying consistent pressure and using the appropriate cutting tools are crucial for achieving the desired results.

Q: How can I achieve smooth and precise cuts on a lathe?

A: To achieve smooth and precise cuts, ensure that the cutting tool is sharp and properly secured. Set the lathe to the appropriate speed for the type of material being worked on. Maintain a steady feed rate and avoid excessive pressure on the cutting tool, as it can cause vibrations and affect the quality of the cut.

Q: What are some common troubleshooting tips for lathe operations?

A: Common troubleshooting tips include checking for loose or worn parts, adjusting the cutting tool geometry, and ensuring proper lubrication of moving parts. Additionally, examining and adjusting the lathe’s settings, such as speed and feed rate, may help solve certain issues.

Q: Any additional advice for beginners using a lathe?

A: Beginners should start with simple projects and gradually progress to more complex ones as they gain experience and confidence. It’s crucial to carefully read and understand the lathe’s manual, seek guidance from experienced individuals, and practice good safety habits to ensure a smooth and fruitful lathe experience. In conclusion, learning how to use a lathe can open up a whole new world of possibilities for the enthusiastic hobbyist or professional craftsman. With the right knowledge and careful attention to safety measures, this versatile machine can be a valuable tool in creating precise and intricate wood or metal projects. From turning bowls and spindles to threading and tapering, the lathe offers endless opportunities to unleash your creativity and craftsmanship. Remember to start with basic projects and gradually build up your skills, always following the guidelines and precautions outlined in this guide. With practice and patience, you can master the art of working with a lathe and experience the satisfaction of transforming raw materials into finely crafted pieces. Embark on this exciting journey and let the lathe become an indispensable addition to your workshop. Happy turning!