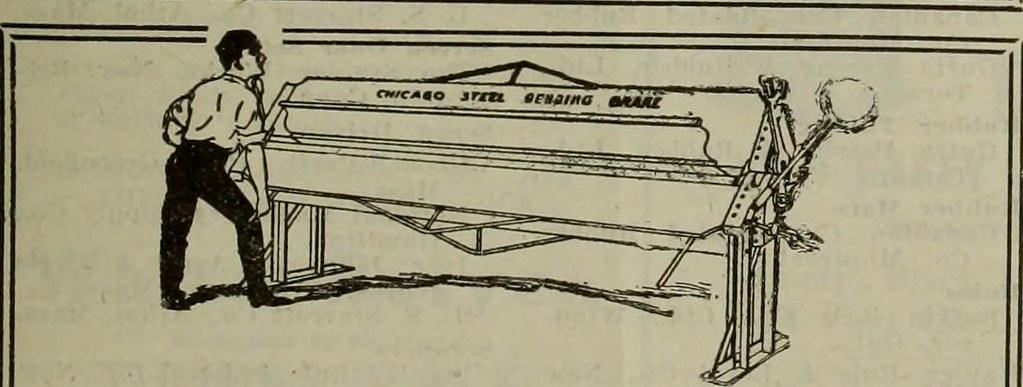

Sheet metal brakes are valuable tools that enable artisans and metalworkers to shape and bend sheet metal with precision and efficiency. With their sturdy frames and movable clamping arms, sheet metal brakes provide a reliable solution for creating smooth, accurate bends in various materials. Whether you’re a novice or an experienced craftsman looking to expand your metalworking skills, understanding how to effectively operate a sheet metal brake is essential. In this article, we will guide you through the step-by-step process of using a sheet metal brake, equipping you with the knowledge and techniques required to achieve professional-grade bends and folds. So, let’s dive in and discover the ins and outs of this indispensable tool.

Introduction to Sheet Metal Brakes

Sheet metal brakes are essential tools for bending and shaping sheet metal with precision and ease. Whether you’re a professional metalworker or a DIY enthusiast, learning how to use a sheet metal brake can open up a world of possibilities for your projects. In this article, we’ll provide a comprehensive , covering everything from their components to their operation and maintenance.

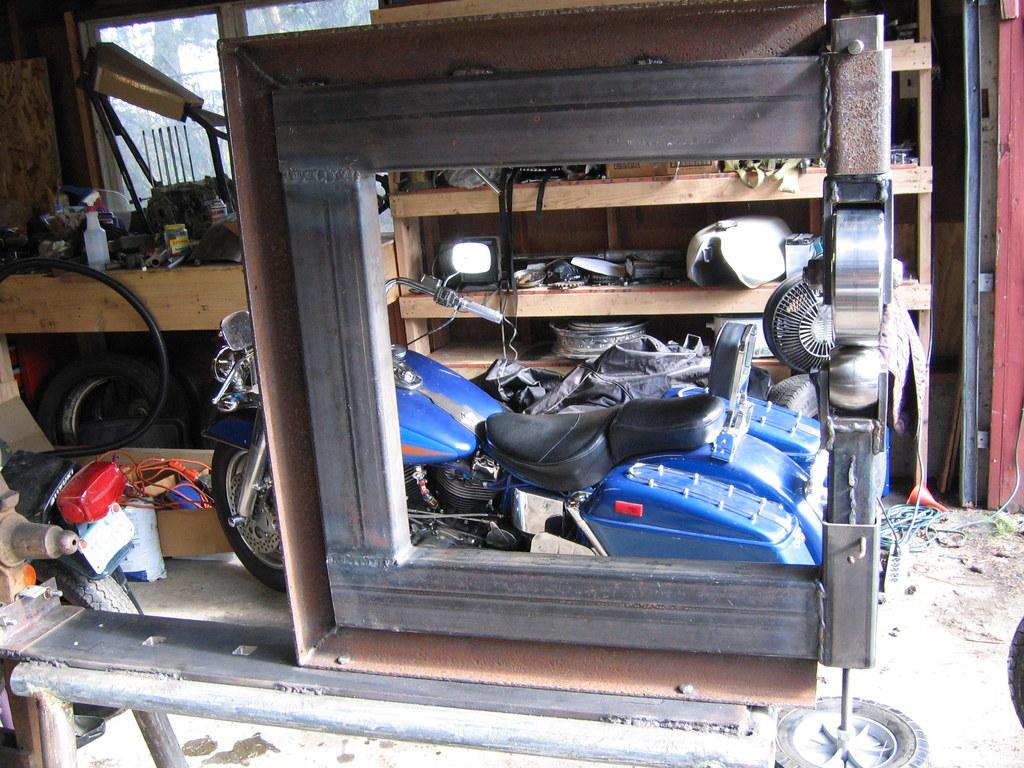

Components of a Sheet Metal Brake

Before diving into how to use a sheet metal brake, it’s important to familiarize yourself with its key components. A typical sheet metal brake consists of a sturdy frame, a bending leaf, and an adjustable clamp bar. The bending leaf is the main working part of the brake and is used to apply pressure to the sheet metal, while the clamp bar keeps the sheet metal in place during the bending process. Some sheet metal brakes also feature additional components like removable fingers that allow for more precise bends.

Getting Started with a Sheet Metal Brake

To use a sheet metal brake effectively, you’ll first need to prepare your work area. Make sure you have sufficient space to maneuver the sheet metal and that the brake is properly secured to prevent any accidents. Next, choose the appropriate gauge of sheet metal for your project and measure and mark the location of the bend or bends. It’s a good idea to use a straight edge or a square to ensure the marks are accurate.

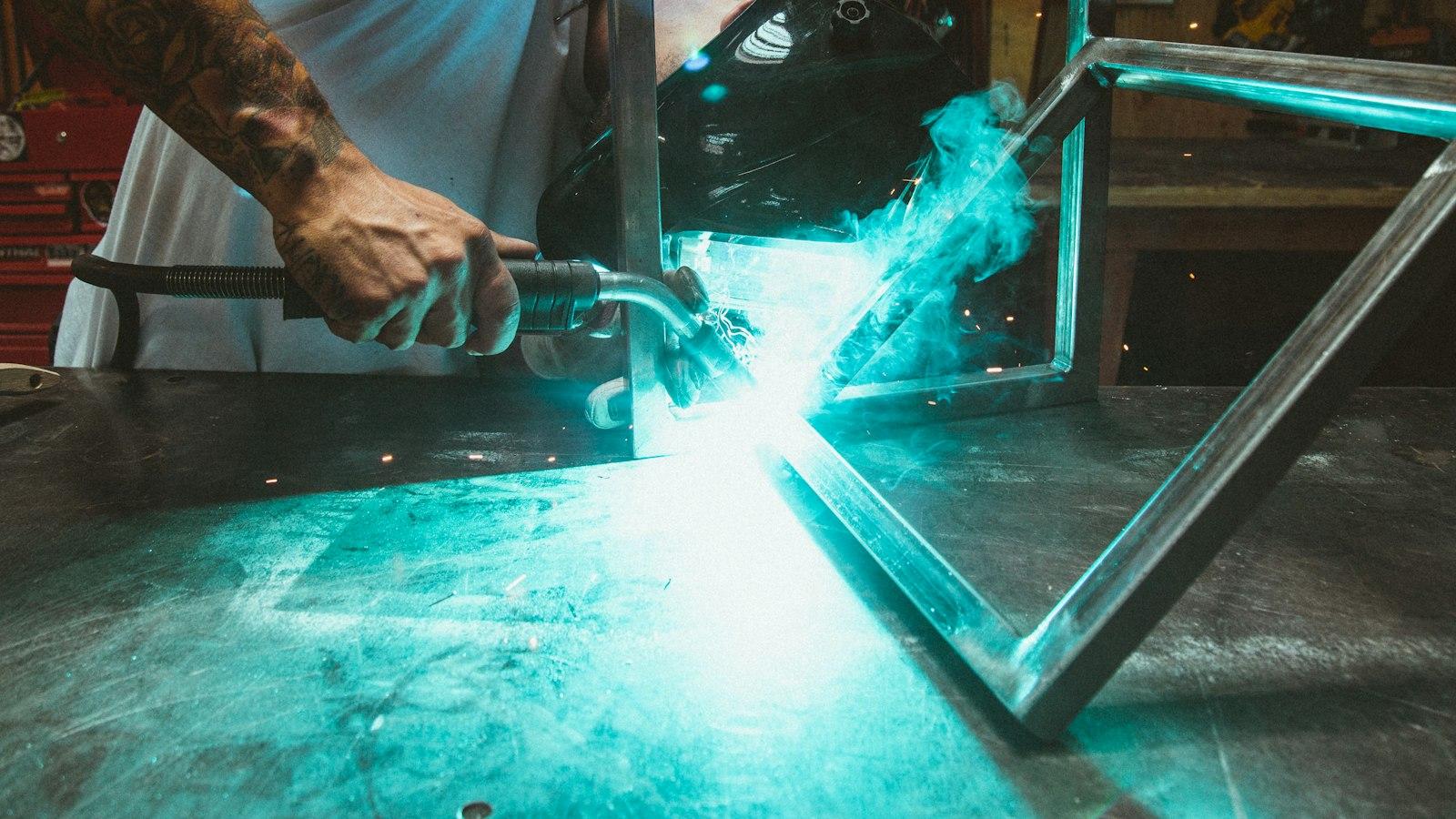

Using a Sheet Metal Brake for Bending

With your work area set up and the sheet metal marked, it’s time to start bending. Place the sheet metal between the bending leaf and the clamp bar, making sure it is aligned with your marks. Secure the clamp bar tightly to hold the sheet metal in place. Then, using the bending leaf, apply gradual pressure to create the desired bend. It’s important to take your time and apply consistent pressure for a smooth and even bend. You can make multiple bends by repositioning the sheet metal and repeating the process.

Maintenance and Safety Tips

To keep your sheet metal brake in optimal condition and ensure your own safety, regular maintenance is crucial. Clean the brake after each use, removing any debris or shavings. Lubricate moving parts as recommended by the manufacturer to prevent rust and ensure smooth operation. Additionally, regularly inspect the brake for any signs of wear or damage, and replace any worn-out parts immediately. Remember to always wear appropriate personal protective equipment, such as safety glasses and gloves, when using a sheet metal brake.

In conclusion, learning how to use a sheet metal brake can greatly enhance your capabilities as a metalworker. By understanding its components, preparing your work area, and following proper bending techniques, you’ll be able to create precise and accurate bends in sheet metal for a variety of projects. Don’t forget to prioritize safety and perform regular maintenance on your brake to ensure its longevity and your own well-being.

Key Components and Functions of a Sheet Metal Brake

A sheet metal brake is an essential tool for anyone working with sheet metal, as it allows you to create precise bends and folds. Understanding its key components and functions is crucial to using it effectively. In this post, we will explore the main components and functions of a sheet metal brake, empowering you with the knowledge needed to master this versatile tool.

Key Components:

-

Bending Bed: This is the flat, horizontal surface where you place the sheet metal for bending. It is made from a durable material like steel and features various measurement markings to ensure accurate bending.

-

Clamp Bar: The clamp bar secures the sheet metal in place during the bending process. It can be adjusted to accommodate different sheet sizes and thicknesses.

-

Apron Leaf: Located below the bending bed, the apron leaf provides extra support and stability to the sheet metal when bending. It is usually adjustable, allowing for various bend angles.

-

Handles: Sheet metal brakes are equipped with handles that connect to a bending leaf or beam. They are used to apply force and create the desired bend. Some brakes have multiple handles for increased leverage and control.

-

Back Gauge: The back gauge functions as a measuring guide and allows for consistent, repeatable bends. It can be adjusted to the desired distance from the bending bed, ensuring accurate and uniform bends.

Functions:

-

Bending: The primary function of a sheet metal brake is to bend sheet metal at precise angles. By adjusting the clamp bar and back gauge, you can achieve various bend angles to match your project requirements.

-

Folding: In addition to bending, a sheet metal brake can also perform folding operations. Folding involves creating a bend along a straight line, allowing you to create edges or seams for joining multiple pieces of sheet metal.

-

Straightening: A sheet metal brake can also be used to straighten bent or warped sheet metal. By carefully aligning the metal with the bending bed and applying pressure, you can restore its flatness and shape.

-

Hemming: Hemming is a technique used to create a secure, folded edge along a sheet of metal, providing increased strength and preventing sharp edges. With the back gauge and clamp bar, a sheet metal brake can easily accomplish this function.

-

Box and Pan Bending: Some sheet metal brakes feature removable fingers or blocks that enable box and pan bending. This technique allows you to create complex shapes and boxes by bending the metal around the fingers.

In conclusion, a sheet metal brake is a versatile tool that empowers you to bend, fold, straighten, and create various shapes with sheet metal. By understanding its key components and functions, you can confidently use this tool to achieve precise and professional results in your sheet metal projects.

Preparing the Sheet Metal for Bending

To effectively use a sheet metal brake, it is essential to properly prepare the metal for bending. By taking the time to prepare the sheet metal correctly, you can ensure clean and accurate bends, minimizing the risk of cracks or other issues. Here are some key steps you should follow when preparing sheet metal for bending:

-

Clean the sheet metal: Before bending the sheet metal, it is important to remove any dirt, oil, or debris from its surface. Use a mild detergent and a clean cloth to wipe down the metal, ensuring it is free from any contaminants that could affect the bending process.

-

Mark the bending line: To achieve precise bends, it is crucial to mark the bending line on the sheet metal. Measure and mark the desired location of the bend using a ruler or square. Ensure that the line is clear and visible, as it will guide you during the bending process.

-

Calculate the bend allowance: Before making any bends, it is important to calculate the bend allowance. This is the amount of material that will be consumed by the bend and needs to be accounted for when determining the final dimensions of the sheet metal. There are various online calculators available to help you determine the bend allowance based on the thickness and type of metal you are working with.

-

Secure the sheet metal: To prevent movement and ensure accurate bends, it is recommended to secure the sheet metal in place. This can be done using clamps or by utilizing the built-in clamping mechanism of the sheet metal brake. Ensure that the metal is firmly held in place to avoid any shifting or misalignment during the bending process.

-

Start the bending process: Once the sheet metal is properly prepared, marked, and secured, you can begin the bending process using the sheet metal brake. Follow the manufacturer’s instructions for your specific brake model, setting the appropriate angle and making incremental bends until the desired shape is achieved. Take your time and make sure each bend is precise before moving on to the next.

By following these steps to prepare your sheet metal for bending, you can achieve accurate and professional-looking results with your sheet metal brake. Remember to always prioritize safety and to refer to the manufacturer’s guidelines and recommended practices when using any equipment or tools. With proper preparation and technique, you can successfully bend sheet metal for a wide range of applications.

Using a Sheet Metal Brake: Step-by-Step Guide

A sheet metal brake is a crucial tool for bending and shaping sheet metal accurately and efficiently. Whether you’re a professional fabricator or a DIY enthusiast, understanding how to use a sheet metal brake is essential for your projects. In this step-by-step guide, we will walk you through the process of using a sheet metal brake effectively.

First, ensure you have all the necessary safety equipment. Before operating the sheet metal brake, put on safety goggles, gloves, and a dust mask to protect yourself from any potential hazards. Safety should always be your top priority when working with any type of machinery.

Once you have your safety gear on, start by setting up the sheet metal brake. Most brakes have adjustable fingers, which allow you to create different bends and angles. Adjust the fingers according to the required measurements for your desired bend. Using a wrench, tighten the locking nuts on each finger to secure them in place.

Next, prepare your sheet metal for bending. Remove any dirt, grease, or debris from the surface that could affect the quality of the bend. Ensure that the sheet metal is clean and dry before placing it into the brake. Smooth out any wrinkles or imperfections to ensure a precise fold.

Now, it’s time to position the sheet metal in the brake. Place the metal piece between the fingers, lining it up with the desired bend. Make sure the sheet metal is aligned properly with the finger grooves to prevent any unwanted deviations. Once aligned, apply gentle pressure to hold the metal in place.

Finally, it’s time to make the bend. Slowly pull down the handle of the brake, applying consistent and even pressure. Keep an eye on the metal as you bend it, ensuring it follows the desired angle. Opt for multiple passes if necessary, gradually increasing the pressure to create a clean, accurate bend. Once you achieve the desired angle, release the brake’s handle to lock the bend in place.

Using a sheet metal brake requires precision and attention to detail. By following these steps, you can confidently utilize this tool to create professional-grade bends in your sheet metal projects. Remember, practice makes perfect, so don’t be discouraged if your first bends aren’t flawless. With time and experience, you’ll master the art of using a sheet metal brake efficiently.

Tips and Safety Precautions for Working with a Sheet Metal Brake

Working with a sheet metal brake can be an efficient and reliable way to bend and shape metal sheets for various projects. To ensure your safety and the success of your work, it is important to follow some tips and take necessary precautions when using a sheet metal brake.

1. Wear Protective Gear:

- Always wear safety glasses to protect your eyes from flying debris.

- Wear gloves to avoid cuts and scratches while handling the metal sheets.

- Use ear protection if the noise level becomes too loud.

2. Familiarize Yourself with the Equipment:

- Read the manufacturer’s manual before using the sheet metal brake.

- Ensure you are familiar with the brake’s controls and settings.

- Inspect the brake for any damages or loose parts before starting your work.

3. Plan and Measure:

Prior to using the sheet metal brake, take the time to plan and measure your project. This will help to prevent mistakes and ensure accurate bends. Consider the following:

- Measure and mark the bend lines on the metal sheet.

- Plan the order of your bends to minimize adjustments and maximize efficiency.

- Take into account the thickness and type of metal you are working with for the appropriate settings on the brake.

4. Adjust and Secure:

Before bending the metal, make sure to adjust and secure the sheet metal brake properly:

- Position the metal sheet between the clamping jaws securely.

- Adjust the bending blade height and angle according to your desired bend.

- Double-check all adjustments before proceeding.

5. Practice and Test:

Before working on your actual project, it is recommended to practice and test on scrap material.

Table: Common Sheet Metal Brake Settings

| Material Thickness | Bending Angle | Blade Height |

|---|---|---|

| 0.025″ – 0.050″ | 90° | 0.25″ |

| 0.051″ – 0.080″ | 90° | 0.375″ |

| 0.081″ – 0.100″ | 90° | 0.5″ |

Remember, using a sheet metal brake requires practice and attention to detail. By following these tips and safety precautions, you will be on your way to efficiently and effectively working with a sheet metal brake for your projects.

Q&A

Q: What is a sheet metal brake?

A: A sheet metal brake is a versatile tool used for shaping and bending sheet metal. It is commonly used in metalworking and fabrication processes.

Q: How does a sheet metal brake work?

A: A sheet metal brake works on the principle of creating leverage to bend and shape the metal. It consists of a flat surface called the bed, which has a clamping bar or beam that holds the metal securely in place. By manipulating a bending leaf or a handle, the metal is pressed against a predetermined edge on the bed, resulting in a precise bend.

Q: What are the common types of sheet metal brakes?

A: The most common types of sheet metal brakes are Box and Pan brakes, Press brakes, and Cornice brakes. Box and Pan brakes have removable fingers that allow for creating various box or pan-like shapes. Press brakes use hydraulic or mechanical force to bend and shape metal, offering greater precision. Cornice brakes are portable and specifically designed for creating cornice shapes.

Q: What are some safety precautions to consider when using a sheet metal brake?

A: Safety is crucial when operating a sheet metal brake. Some precautions to consider include: wearing personal protective equipment (PPE) such as gloves and safety goggles, ensuring the machine is properly grounded, always using the proper tools and equipment, and paying attention to the operator’s manual for specific safety instructions.

Q: What are some key tips for using a sheet metal brake effectively?

A: To use a sheet metal brake effectively, it is important to accurately measure and mark the metal, align it properly with the bending point, and securely clamp it in place. Additionally, understanding the machine’s capacity and limitations, practicing patience, and making precise adjustments when necessary will greatly improve the overall results.

Q: What are the advantages of using a sheet metal brake?

A: Using a sheet metal brake offers several advantages, including the ability to create precise and consistent bends, increased efficiency in shaping metal, cost-effectiveness in small-scale projects, and ease of use for both beginners and experienced metalworkers.

Q: Can a sheet metal brake be used for materials other than metal?

A: Yes, although primarily designed for sheet metal, a sheet metal brake can also be used to bend and cut plastic sheets, aluminum, brass, and some thin wooden materials. However, it is important to consider the specific limitations and capabilities of the machine before attempting to work with non-metal materials.

Q: Are there any common mistakes to avoid when using a sheet metal brake?

A: Some common mistakes to avoid when using a sheet metal brake include not properly adjusting the clamping bar or bending leaf, using excessive force that could damage the machine or the metal, and ignoring safety precautions. It is important to carefully read and follow the instructions provided by the manufacturer before operating the machine.

Q: How can I maintain and care for my sheet metal brake?

A: Proper maintenance of a sheet metal brake includes regular cleaning to remove dust and debris, lubricating all moving parts, and checking for any loose or damaged components. It is recommended to refer to the manufacturer’s instructions for specific maintenance guidelines and to have the machine serviced by a professional if needed. In conclusion, understanding how to use a sheet metal brake successfully can open up a world of possibilities for DIY enthusiasts and professionals alike. The step-by-step process outlined in this article serves as a helpful guide to ensure accurate bends, precise measurements, and overall efficient operation. Remember to always prioritize safety, wear appropriate protective gear, and carefully read and follow the manufacturer’s instructions for your specific sheet metal brake model. With a solid foundation of knowledge and practice, you can confidently tackle projects that require precise metal bending, saving both time and money. Whether you are a seasoned metalworker or a passionate hobbyist, mastering the art of using a sheet metal brake is an invaluable skill that allows you to bring your creative visions to life. So, equip yourself with the necessary tools, familiarize yourself with the techniques discussed, and get ready to bend and shape metal with precision and ease.